What is NP3 Coating?

NP3 coating is a type of electroless nickel plating that is known for its exceptional resistance to wear, corrosion, and friction. It is commonly used in firearms, automotive, and industrial applications where durability and reliability are essential.

Unlike traditional nickel plating, NP3 coating is applied through a chemical process that does not require an electrical current. This results in a more uniform and consistent coating, with no buildup or unevenness. The coating is also highly lubricious, which helps to reduce friction and wear on moving parts.

NP3 coating is a composite of nickel, phosphorus, and Teflon. The Teflon particles are evenly distributed throughout the nickel matrix, providing a low coefficient of friction and excellent lubricity. This makes NP3 coating ideal for use in high-stress applications where parts are subject to extreme wear and tear.

In addition to its superior wear resistance, NP3 coating is also highly resistant to corrosion and chemicals. It provides a barrier against moisture and other corrosive elements, which helps to extend the life of the coated part. NP3 coating is also biocompatible, making it suitable for use in medical and dental applications.

Np3 Coating Benefits

NP3 coating is a type of electroless nickel plating that is combined with a PTFE (polytetrafluoroethylene) coating. This makes it a very durable and self-lubricating coating that is often used on firearms.

Here are some of the benefits of NP3 coating:

- Corrosion resistance: NP3 coating is very resistant to corrosion, even in harsh environments. This makes it a good choice for firearms that will be used in wet or humid conditions.

- Lubricity: The PTFE in the NP3 coating provides excellent lubricity, which reduces friction and wear on moving parts. This can help to extend the life of your firearm.

- Durability: NP3 coating is very durable and can withstand a lot of abuse. This makes it a good choice for firearms that will be used in heavy use or in harsh environments.

- Ease of maintenance: NP3 coating is very easy to maintain. You don’t need to apply any additional lubricants, and it can be cleaned with just soap and water.

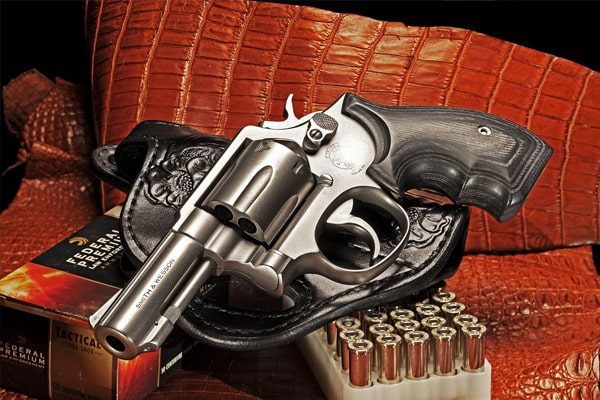

- Appearance: NP3 coating has a smooth, polished finish that looks great on firearms.

Overall, NP3 coating is a very beneficial coating for firearms. It is corrosion resistant, lubricated, durable, easy to maintain, and looks great. If you are looking for a high-quality coating for your firearm, NP3 is a great option.

Here are some specific examples of how NP3 coating can benefit firearms:

- Trigger mechanisms: NP3 coating can help to smooth out the action of a trigger mechanism and make it more responsive. This can be a big advantage in competition shooting or self-defense situations.

- Barrels: NP3 coating can help to protect a barrel from corrosion and wear. This can extend the life of the barrel and improve accuracy.

- Bolt carriers: NP3 coating can help to reduce friction and wear on a bolt carrier. This can improve reliability and accuracy.

- Other parts: NP3 coating can be applied to any part of a firearm that needs protection from corrosion, wear, or friction.

If you are considering NP3 coating for your firearm, it is important to talk to a qualified gunsmith to get their recommendations. They can help you determine if NP3 coating is the right choice for your firearm and specific needs.

How Durable is NP3 Coating?

NP3 coating is very durable and can withstand a lot of abuse. It is often used in aerospace and other demanding applications where corrosion resistance and durability are critical.

In terms of firearms, NP3 coating has been shown to exceed a 250-hour salt spray test, which is a standard test for corrosion resistance. It is also very resistant to wear and tear, and can withstand high temperatures and pressures.

As a result of its durability, NP3 coating is often used on parts of firearms that are subject to a lot of wear and tear, such as trigger mechanisms, barrels, and bolt carriers. It can also be used on other parts of a firearm that need protection from corrosion, such as the slide and frame.

If you are looking for a durable and corrosion-resistant coating for your firearm, NP3 is a great option. It is a proven coating that has been used in demanding applications for many years.

Advantages of NP3 Coating

NP3 coating is a popular surface coating used in a variety of applications. Here are some of the advantages of using NP3 coating:

- Corrosion Resistance: NP3 coating is highly resistant to corrosion, even in harsh environments. This makes it an ideal choice for parts that are exposed to saltwater or other corrosive substances.

- Wear Resistance: NP3 coating is also highly wear-resistant, making it an excellent choice for parts that are subject to heavy use or friction. This can help extend the lifespan of parts and reduce maintenance costs.

- Lubricity: NP3 coating has a low coefficient of friction, which means that parts coated with NP3 have excellent lubricity. This can help reduce friction and wear, as well as improve the overall performance of the part.

- Appearance: NP3 coating has a unique appearance that is both attractive and functional. The coating has a matte gray finish that is both durable and aesthetically pleasing.

In addition to these advantages, NP3 coating is also easy to apply and can be used on a wide range of materials, including steel, aluminum, and titanium. This makes it a versatile coating that can be used in a variety of applications.

Applications of NP3 Coating

NP3 coating is a versatile coating that can be used in a variety of applications. Here are some of the most common uses:

- Firearms: NP3 coating is commonly used on firearms to improve their durability and reliability. The coating helps protect the gun from wear and tear, corrosion, and other types of damage. It also reduces friction between moving parts, which can improve accuracy and reduce recoil.

- Aerospace: NP3 coating is used in the aerospace industry to protect critical components from wear, corrosion, and other types of damage. The coating can be applied to a variety of materials, including aluminum, titanium, and magnesium.

- Automotive: NP3 coating is used in the automotive industry to improve the durability and performance of engine components, such as pistons, bearings, and crankshafts. The coating helps reduce friction and wear, which can improve fuel efficiency and extend the life of the engine.

- Military: NP3 coating is used by the military to protect weapons and other equipment from wear, corrosion, and other types of damage. The coating can be applied to a variety of materials, including steel, aluminum, and titanium.

Overall, NP3 coating is a reliable and effective coating that can be used in a variety of applications. Its ability to reduce friction, protect against corrosion, and improve durability make it a popular choice for many industries.

NP3 Coating Process

At our facility, we utilize a unique process to apply NP3 coating to various firearms and components. The process involves a series of steps that ensure a consistent and durable coating.

First, the parts are thoroughly cleaned and degreased to remove any contaminants. This step is crucial to ensure proper adhesion of the coating.

Next, the parts are placed in a preheating oven to bring them up to the desired temperature. This step helps to ensure that the coating will properly bond to the surface of the parts.

After preheating, the parts are transferred to a spray booth where the NP3 coating is applied using a specialized spray gun. The coating is applied in a thin, even layer to ensure proper coverage and adhesion.

Once the coating is applied, the parts are transferred to a curing oven where they are heated to a specific temperature for a set amount of time. This step is critical to ensure that the coating fully cures and hardens, creating a durable and long-lasting finish.

Finally, the parts are inspected for quality control and any necessary touch-ups are made before they are packaged and shipped back to the customer.

FAQs Np3 coating

Q: What are the benefits of using Np3 compared to other coatings?

A: The main benefit of using Np3 compared to other coatings is its increased corrosion resistance. This means that parts coated with this material will last longer and require less maintenance over time. Additionally, the increased lubricity of Np3 means that friction between moving parts is significantly reduced; this not only aids in accuracy but also prevents wear on components. Finally, Np3’s extra hard surface makes it more resistant to scratches and abrasions than other coatings, further increasing its longevity and performance.

Q: What type of firearms is Np3 best suited for?

A: Np3 works well on all types of firearms including handguns, rifles, shotguns, and even some machine guns. The coating offers superior protection against corrosion which can be beneficial for firearms used in harsh environments or exposed to water frequently. In addition, the improved lubricity provided by Np3 can help to increase the accuracy and performance of firearms.

Q: How long does it take for Np3 coating to be applied?

A: The time required to apply Np3 coating depends on the size and complexity of the firearm being coated as well as any other treatments or coatings that may need to be applied beforehand. Generally, a complete application should take about 1-2 hours for handguns and up to 6-8 hours for more complex firearms such as machine guns.

Q: Is Np3 safe to use on my firearm?

A: Yes, Np3 is completely safe to use on all firearms, provided it is installed correctly. Before applying the coating, it is important to make sure that all parts of the firearm are cleaned and prepared properly. Additionally, it is recommended that you use an experienced professional for the installation process in order to ensure optimum results.

Q: Is Np3 difficult to maintain?

A: No, Np3 does not require a lot of maintenance once applied. The coating provides superior protection against corrosion which eliminates the need for frequent cleaning or servicing. The only maintenance required is occasional lubrication in order to keep moving parts functioning smoothly. In addition, if any scratches or abrasions occur on the surface of the gun, these can be easily repaired with a mild steel wool pad and some oil.

Q: How long does Np3 coating typically last?

A: The lifespan of the Np3 coating depends on the environment in which it is used and how well it is maintained. Generally, a good Np3 coating can last anywhere from 10-15 years with proper maintenance. Additionally, if any parts of the gun need to be replaced during this time, they can easily be re-coated with Np3 without any problems. This ensures that your firearm will remain protected for many years to come.

Conclusion

After conducting thorough research and analysis, we have concluded that Np3 coating is a highly effective and reliable solution for enhancing the durability and performance of firearms and other metal components.

With its superior corrosion resistance, wear resistance, and lubricity, Np3 coating provides a long-lasting protective barrier that can withstand even the harshest environments and conditions.

Furthermore, Np3 coating offers a number of other benefits, including improved accuracy, reduced friction, and easier maintenance. Whether you are a competitive shooter, a law enforcement officer, or a military operator, Np3 coating can help you achieve your goals and perform at your best.

Overall, we highly recommend Np3 coating as a top-of-the-line solution for anyone looking to protect and optimize their firearms or other metal components. With its proven track record of success and its many benefits, Np3 coating is the clear choice for those who demand the best.

Last Updated on October 28, 2023 by